Excavating

Rocks - Rip-able or Un-rip-able

Road

engineers often have to face the challenge on

deciding whether the roads they designed at hilly/ mountainous areas, can be excavated cheaply so as to

achieve safe and gentle road gradient for the road users. Of course, the

engineers can design to the safest gradient theoretically with the latest high

capacity excavating equipments and blasting, but the cost can be exorbitant

which renders the project not feasible. This is particular true for under

developed countries where budgets are limited. Modern living requires shortest

distance and safest road gradient between the two points. In the mountain

regions, mountains have to be excavated and valleys filled up or bridges built

to satisfy such needs. But deep excavation often encounters hard rocks and rock

excavation is expensive. It generally costs about US$2-4 to excavate and filling

of soils, but will cost more than US$10-20 to excavate rocks, depending on the

remoteness of the project sites. A balance has to be made between safety,

comforts, distance and costs. The knowledge of the machineries available

locally and rip-ability of local rocks become important so that the designers

can decide which lowest and most

economical excavated levels the local builders can achieve.

These photos show the 20 ton capacity

excavator being used to rip the rock. Obviously, this machinery is not suitable

for ripping as capacity is low and the energy splits between the many teeth of

the dipper. But as the rock is Shale, a soft rock, he may be able to rip

slowly. But much energy is lost through friction and heat. Perhaps, this

Contractor feels freer and economical to use his own available machine then to

rent a D8 bulldozer with the ripper from others.

On the local scene, D8L with the ripper, having 335 horse power and weighing 25 tons, is the standard machinery specified to

decide whether the rock is to be paid “rock rate”. If it is able to be ripped

by this machine, then it is considered “earth or non-rock”. If not, it is paid

“rock rate”. But in view of the high difference in cost, the Contractor

obviously wants to claim rock rate while the client wishes to pay only non-rock

rate. Thus Contractor may use an under-powered D8L to prove his point or even

ask the drivers to cheat on the use of gears or operations so as to show the

rock is not rip-able. Sometimes, road projects were abandoned because of this

controversy, especially if the engineers provide low quantities of un-rip-able rock

in the Contract. Of course, the design engineers can re-design the gradients to

minimise rock excavation, but the safety of the roads may be compromised

beside delay of projects. I remembered one road with a road gradient of 25% in

some stretch to a hill resort, became accident prone stretch within one month

of the opening. The cost and safety of the road is closely related.

But how to determine whether the rock is

rip-able or not? Engineers nowadays easily acquire road design software to come

out with beautiful lines, graphs, figures to even two decimals, cross-sections

and quantities. But to estimate the non-rip-able rock from this standard software is beyond its capabilities. The engineers have to decide which level is the cut-off point as even 10m away may be different.

The knowledge of geology is the first

pre-requisite. It is fortunate that the earlier geologists had come out with a Geological

Map of Sarawak, mapping all the different features, geological history and types

of rocks of Sarawak at different regions. These geologists of Sarawak

Geological Department were great enthusiasts, scientists and explorers, who

despite the inaccessible and difficult tropical terrains, ventured to the

ground, studied diligently under the hot sun for years during the last century

and came out with the geological reports and Maps, which had benefited the geologists/geotechnical engineers today, including me. I saluted them. The fourth edition

dated 1986 could be purchased from the Sarawak Geological Department and I often

referred to this Map.

Soil investigation is the next important

step. Although geological map is a helpful preliminary investigation, detailed

soil investigation will confirm the actual nature of the rocks beneath the

proposed road. After all, earlier Geologists used generally visual observations

of exposed outcrops, features, plus limited borehole drilling to come out the

geological map. Some local variations or intrusions of rocks may happen during

the tumultuous age of mountain buildings. Types of rocks will straight away

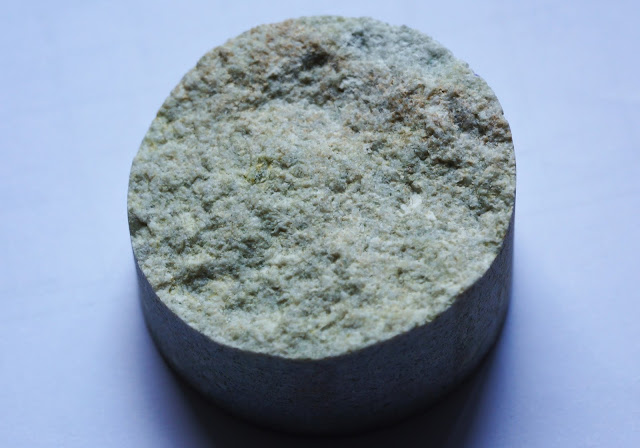

determine whether the rocks are rip-able or not. Igneous rocks, such as

Granite, Andesite, Gabbro, Basalt, Microtonalite, etc are generally difficult

to rip, unless they are thinly laminated. Sedimentary rocks such as Shale, Siltstone, Mudstone, etc are generally

easier to rip, but not the Limestone which is strongly bonded by chemical and can

reach a strength of exceeding 30N/sq.mm unconfined strengths. As of metamorphosed

rocks, Quartzite, Schist’s, Gneisses and Slates can be difficult to rip

depending on the lamination, mica content and degree of weathering. Drilling

boreholes can extract the rock cores beneath the ground for which the Geologists

and the Geotechnical Engineers can study the rock samples.

Together with Total Recovery Ratio (TCR) and Rock Recovery Designation (RQD),

some feelings on the rock rip-ability can be made but not absolute. Drilling

procedures, such as vibrations and water entries may produce totally shattered

samples, which appear easily rip-able.

Seismic survey is sometimes deployed for

larger road projects. Caterpillar (1983) and Smith(1986) had co-related

Rip-able Charts with their research on seismic survey, and are helpful in

determining the rip-ability of rocks. Seismic velocity travels 0.3km/s in loose

unsaturated soils, but reaches 6km/s in hard rocks. Generally, velocity of

2.0km/s is rip-able while >2.5km/s is unlikely. In between, it is the grey

area.

The most popular available excavating

machineries used for road construction in Sarawak are Caterpillar D6 bull dozers

and 20 tons excavators, mainly at lowlands and small hill areas. But D8 dozers

are only owned by some big construction companies. D8L is probably the most

common type which is specified in the local road specification. D8 Dozer had

evolved from 132 horse powers (hp) in 1932 to 335hp D8L in 1982 and 310 hp D8T

in 2004. Power is the most important factor to decide whether the rock is

rip-able.

Dozer had since developed into even more

powerful machineries, D9, D10 and even D11. These machineries are used to

excavate non-rip-able rocks. Although blasting and hydraulically mounted breakers/chisels

are another commonly deployed methods used to excavate hard rocks, but blasting

requires a lot of safety procedures and relevant approvals which quite often

cause delays. Chiselling is too slow for large quantities of rocks. Blasting is

often prohibited near dam sites and other sensitive Equipments installations. Therefore,

D9 and D10 dozers become the only options to excavate un-rip-able rocks in many

areas. These machineries were often used by the large and rich timber corporations

in the interior mountainous areas to build roads to transport their logs. With

the dwindling of the forests, these timber companies had switched to construct

highways which could deploy such machineries. In 1955, D9 had 286hp but by

2004, D9T had reached 410hp. But the most powerful D9 was 1980 D9L with 460hp. Komatsu D275A probably posed a strong

competitor to D9. In 1987, Caterpillar introduced 700hp D10 and 520hp D10N,

weighing 82-86 tons. Komatsu came out with D455A with 620hp and weighed 76

tons. By 1986, Caterpillar produced 770hp D11N weighing about 102 tons with

ripper, and by 2008 developed 850hp, 120 tons D11T. Komatsu responded with

1150hp D575A weighing 168tons. Such huge machines would be damaging to move on

the local roads. I had seen D9 and D10 in the timber concessions, but I am not

sure whether there is any D11 bull dozer in Sarawak.

Availability of large excavation

machineries does not mean cheaper rock excavation cost. These machineries are expensive to procure, and probably not only the manufacturers monopolise the market, the

owners also monopolise the local construction market. When budgets are

limited or the country is poor, Engineers have to propose a design of steeper

gradients with less excavation, slower speeds and longer routes. Road users have

to be more careful, drive slowly and ensure that their cars are maintained

road-worthy.

When you are poor, you cannot expect too much.